Technical Services Department

Tel: 01234 344108 Email: technical@marleyalutec.co.uk

We have products to suit a wide range of aesthetics, drainage requirements and environments. Our Technical Services Department can advise which of our products are suitable for your specific project.

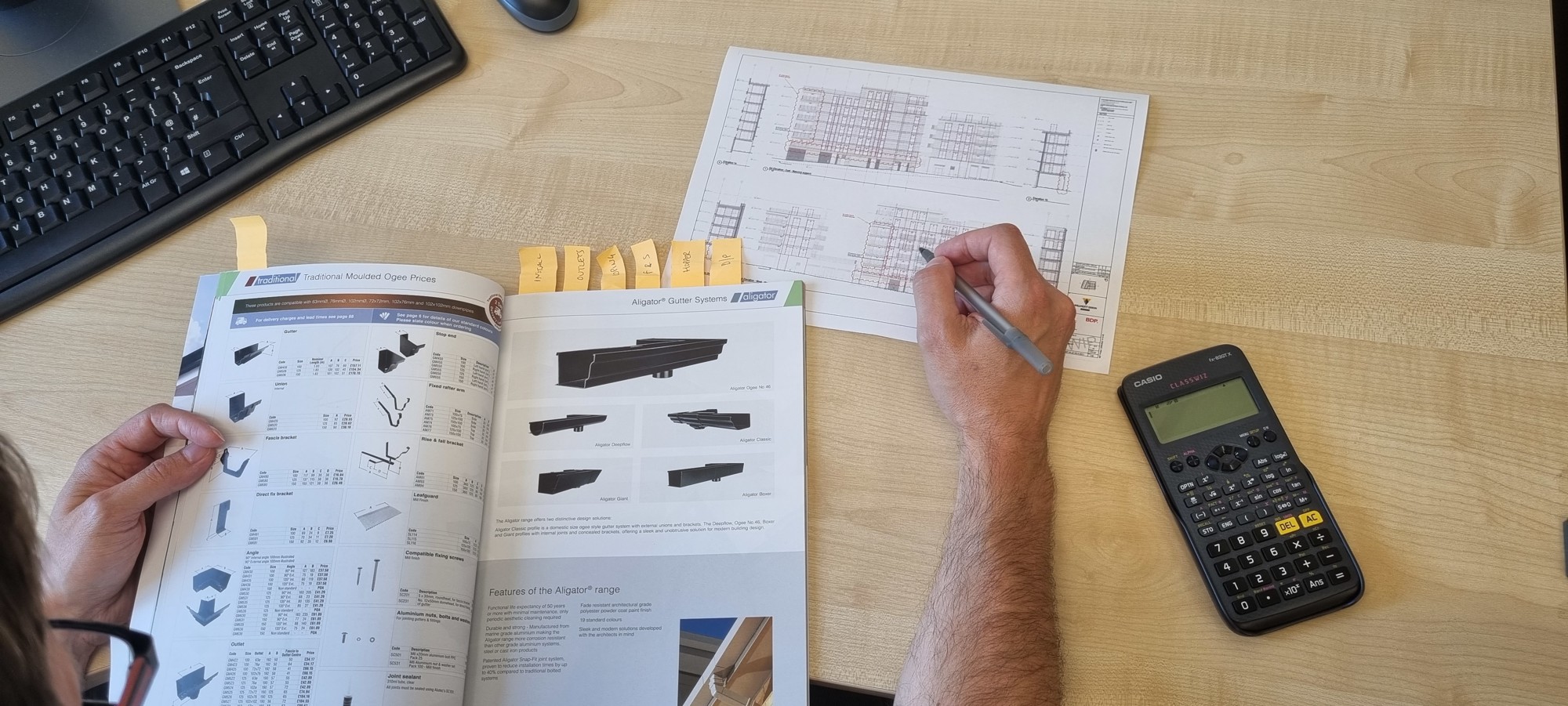

Roof Drainage Design Calculations

To ensure that your project conforms to the correct drainage specifications our Technical Department will produce a full set of drainage calculations based on the information provided. Alternatively, click here to instantly obtain a drainage calculation for your project

Learn more

Installation Advice

All of our products are easy to install, but for specific installation enquiries, our Technical Department are always on hand to advise.

Learn more

Bespoke Design Guidance

While we have a wide range of products for most applications, we understand that there will be circumstances where you will need bespoke products and solutions for your project. Our Technical Services Department can advise you on a solution tailored to your individual project requirements.

Non Standard Bespoke Solutions

Building Information Modelling (BIM)

Marley Alutec was the first rainwater systems manufacturer to offer its entire product range in BIM object format. Our technical department is well versed in BIM design and available to assist specifiers with any queries.

Learn more

Contact Us

fields marked with * are mandatoryWe are committed to listen to our customers and deliver the best ever possible services and technical expertise. Please use the form below to contact us and we will come back to you as soon as possible.